De-sludging, not a pretty phrase is it!? Someone needs to come up with a better name for it, maybe thats why some simply call it 'emptying'? Anyway… de-sludging is the process of removing the settled solids from the bottom and the fats, oils and grease from the top of your treatment plant.

Every treatment plant differs slightly in the way we achieve this but ultimately, we do this with our large vacuum tankers, think big henry hoover on wheels.

We suck out all the gubbins your sewage treatment plant can’t handle or treat and take them off to a large sewage treatment centre who are better equipped to deal with this type of waste. This is where your waste would end up if you were on mains drains.

All this is imperative to give your sewage treatment plant the best chance of continuing to treat the waste as its designed to do. It also stops the build-up from getting too big and potentially blocking up or breaking down the system.

Failing to properly maintain your Septic Tank can have disastrous effects on the environment around you. make sure you are instructing an established, respected and fully licenced waste carrier, like Clearmasters, to look after your sewage system.

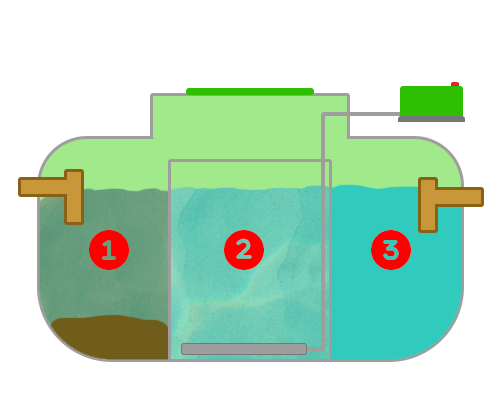

Just the same as a cesspit or septic tank, it all starts with pipework from your property transferring all the sewage and wastewater into the treatment plant, via its inlet, into the first chamber . This chamber serves to split the liquid from the fats, grease, oils and solids. This is often referred to as a primary, settlement or separation chamber.

Once separated the liquids move on to the next chamber for treatment, there are a few ways this treatment takes place depending on the make and model of your treatment plant. Most commonly via air being infused into the tank, a rotating bale or via passing the liquid repeatedly through filters. Although the treatment process is different, they all work to promote the growth of bacteria which thrives on the ‘nastier stuff’ in the liquid, effectively removing it.

We could go more into detail about the practices of anaerobic and aerobic treatment processes, but that would risk putting you to sleep, if you really want to know the in's and out's of your specific system give our office a call and we will be more than happy to run you through it.

After the bacteria has done its job, the treated liquid then moves on to its third and final chamber . Like the first, this is a settlement chamber giving any solids or particles still in the liquid a chance to sink to the bottom of the chamber before it discharges the ‘almost’ drinkable water* to the ground or to a water course.

Show/Hide Labels

*Some manufacturers make the bold claim the final effluent from their systems is drinkable, we are just going to take their word for it! But unless it’s in the name of science, we don’t recommend it!

Absolutely, keeping your sewage treatment plant well maintained will not only keep it working at 100% it can save you a fortune in costly repairs from breakdowns or malfunction.

This needs to be done atleast once a year and would usualy be done around the same time as the de-sludging of you treatmet plant.

The maintence required differs quite a bit depending on what system you have so we have another page with all the details. heres a link...

Quite simply, we are the best!

We are always on hand, whether it be a routine visit, or an emergency call out to offer you the very best in sewage treatment plant de-sludging. We pride ourselves on having a modern fleet of vehicles containing the highest tech equipment to ensure that we can provide you with the high levels of reliability and efficiency that we constantly achieve.

Our friendly and knowledgeable office team, are always available to discuss or advise on any of your treatment plant requirements or simply to schedule in your treatemtn plant emptying at a convenient time and date that suits you.

On site, our team of dedicated, friendly and fully trained engineers will ensure that your emptying is carried out to the highest standard with minimal disruption. Our engineers are always willing and fully encouraged to spend time answering any questions you may have regarding your sewage system.

This list could go on and on, if you are ever unsure about anything relating to your treatment plant just give us a call and check first.

Most systems require desludging at least once a year to prevent sludge build-up beyond capacity and ensure efficient performance. It’s essential to check your manufacturer’s instructions or talk to our team for site-specific guidance. :contentReference[oaicite:0]{index=0}

Excessive sludge can overwhelm the system, reducing its capacity, causing effluent quality problems, soakaway failure or even pollution. Regular maintenance prevents breakdowns and avoids costly emergency call-outs. :contentReference

Typically no – we plan the desludging so your system remains operational or is back in service promptly. Our team handles the access, safe emptying and reinstatement with minimal disruption to your property and processes.

Signs include longer drainage times, unusual smells around the installation, sludge rising toward the outlet pipe or visible solids in the discharge. Inspections can measure sludge depth and advise when desludging is due.

Yes. Removing the excess sludge helps the plant run efficiently, improves the quality of the final discharge and reduces strain on mechanical parts. Regular desludging is one of the simplest ways to extend the life of your system.

Not usually. As long as we have safe access to the treatment plant, we handle everything else. If any covers are heavy or overgrown, let us know in advance and we’ll make sure the right equipment is brought to site.